AI, efficiency & decarbonisation seminar: transforming industry together

How are manufacturers dealing with uncertain business conditions?

Investments in new and sustainable technologies are being held back by various global developments. Geopolitical shifts, volatile trade tariffs and other challenges create an uncertain business environment. Margins and competitiveness are under pressure. At the same time, climate change and upcoming legislation are not exactly put on hold. The need for transforming industry seems greater than ever.

How can AI, efficiency and decarbonisation help improve competitiveness?

Zooming in on this question with global leading companies from the manufacturing sector – across food, pharma, and beyond – the seminar explored innovations, shared best practices and discussed ways to accelerate the transition toward efficiency, sustainable manufacturing, and competitiveness.

Inspiration and best practices

After Marijke Jurgens, Marketing Lead Industry at Haskoning, welcomed all guests, the first of three inspiring keynote speeches followed. Daco Olasolo, Director Future Engineering at Danone, focussed on how to win with AI in manufacturing. An important prerequisite: you must be working towards Closed Loop AI, to enable AI to take decisions and accelerate your operational speed. If you do not know where AI can add value, do not even start. If you do know, implement AI but do it step by step, in a controlled way. With validated data models and operating with the correct context it will accelerate your day-to-day operations.

Stijn Bekers, Design & Engineering Manager at scale-up Protix, took the floor for the second keynote. His company produces insect-based proteins for mainly animal nutrition products and has sustainability at its heart. Harbouring this characteristic, how does Protix balance ambitious goals with pressures of cost-effectiveness?

It is a matter of sticking to your long-term vision, but at the same time staying flexible. When available capital is limited, never be afraid to reconsider previous decisions and think of ways to implement solutions that can be retrofitted later when the financial situation changes.

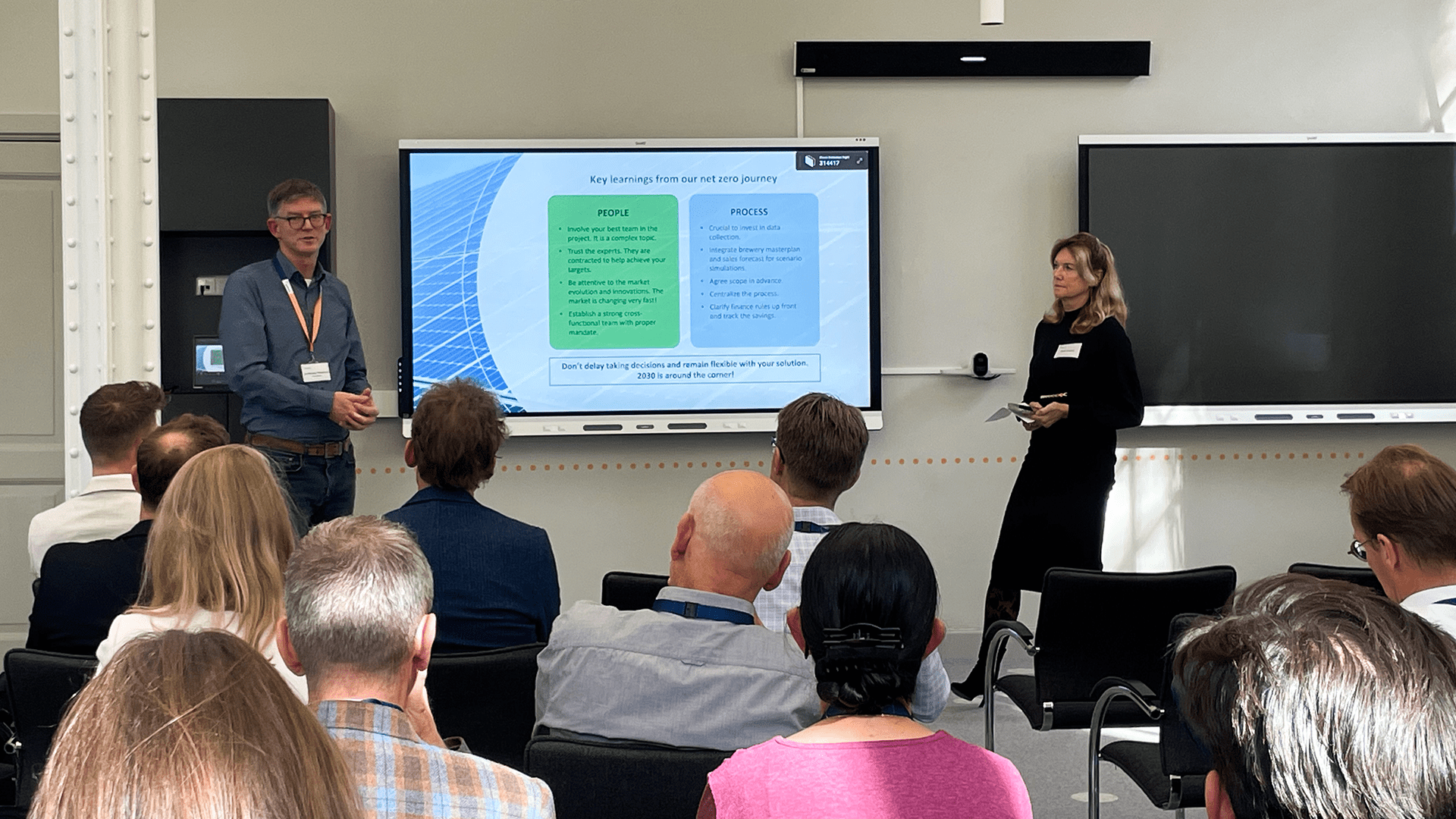

After a short break, during which all participants enjoyed refreshments and the opportunity to catch up with one another, it was Jan-Maarten Geertman’s turn for the third keynote presentation. As Director Sustainable Production at Heineken, he addressed the various ways in which the brewer drives industrial decarbonisation across its 180+ breweries worldwide.

Decarbonisation is not cheap and therefore it is essential to apply the right technology in the right place. Energy reduction is one of those key levers where high gravity brewing, condensate recovery and insulating brewhouse vessels play a major role. Replacing fossil fuels with renewable alternatives can be done by building solar thermal plants next to production facilities.

Currently, you can see CAPEX investments in sustainable production run ahead of the benefits.

Learning together and one on one

Both during the Q&A following each keynote and the various breaks, the participants of the seminar exchanged ideas and experiences eagerly. They discussed their particular challenges and viable solutions, in small groups and individually.Our company’s challenge is funding the necessary investments in carbon-neutral production.

How to overcome the increasing cost of climate change action?

This question was addressed by Wim de Vriendt, Global Manufacturing Technology Lead of Natural Resources and Utilities at Cargill, in his break-out session. As all present seemed to agree that sustainability has to progress anyway, the question narrowed down to: who do we have to convince to do so and how do we do that? One tool are LTI/STI’s (long and short-term incentives for local management to aim for sustainability goals), another one is stakeholder management. But top of the list may be leadership, for sharing a clear vision and setting clear goals.

Is biomass the best-in-class solution?

Susanne Folkerts, Global Operations Head of Sustainability & Environment at Ofi, shared her insights from operating mass boilers that convert residual streams into energy. A lively discussion followed, on alternatives that could be more sustainable or cost-efficient. One conclusion: waiting for the perfect solution is no solution. Make a start with a technology that enhances your process, learn by doing and be alert to new innovations.

Sustainability is not a side project. It is the foundation of resilient businesses who are ready for the future.

Can modelling and simulation really optimise production and packaging?

This break-out session hosted by Duncan Brown, Senior Business Development Manager at Haskoning, focussed on a case study of modelling and simulation reshaping production and packaging lines to boost manufacturing efficiency and sustainability impact. Together, participants explored where simulation tools create value and how they support sustainability goals.It's a wrap!

Susanne Rolaff, Director Advisory Group Project Management & Consultancy Multinationals at Haskoning, wrapped up the material program of the seminar. She summed up some of the contributing factors to strengthening competitiveness in industry, such as vision, leadership, flexibility, AI, data and people – both internal and external. Cherish all staff and partners who can help.

Following the wrap-up, some guests trotted off for a guided tour of the Delft Haskoning office (an old university building transformed sustainably). Others headed directly to the company restaurant to enjoy their networking opportunities – and the buffet.

Get in touch

To learn more about how Haskoning is helping manufacturers to improve competitiveness by transforming industry through AI in manufacturing, manufacturing efficiency, and industrial decarbonisation within the broader journey toward sustainable manufacturing.