Optimised layout enables production to go on as brewhouse is built

Project facts

- Client

- A small brewery producing nearly 300,000 hectolitres annually

- Location

- An island in the Indian ocean

- Challenge

- The operation needed replacing while maintaining continuity of production with a limited space

- Solution

- 3D modelling enabled optimisation to deliver a solution that enabled the brewery to stay operating

The challenge - Replace while running

Our client, a small brewery located on an Indian Ocean island, faced a critical operational hurdle. With an annual production of nearly 300,000 hectoliters, their existing brewhouse had become obsolete and urgently needed replacement. The challenge was twofold: how to upgrade the facility while maintaining uninterrupted operations of the brewery and dealing with additional constraints due to limited space.

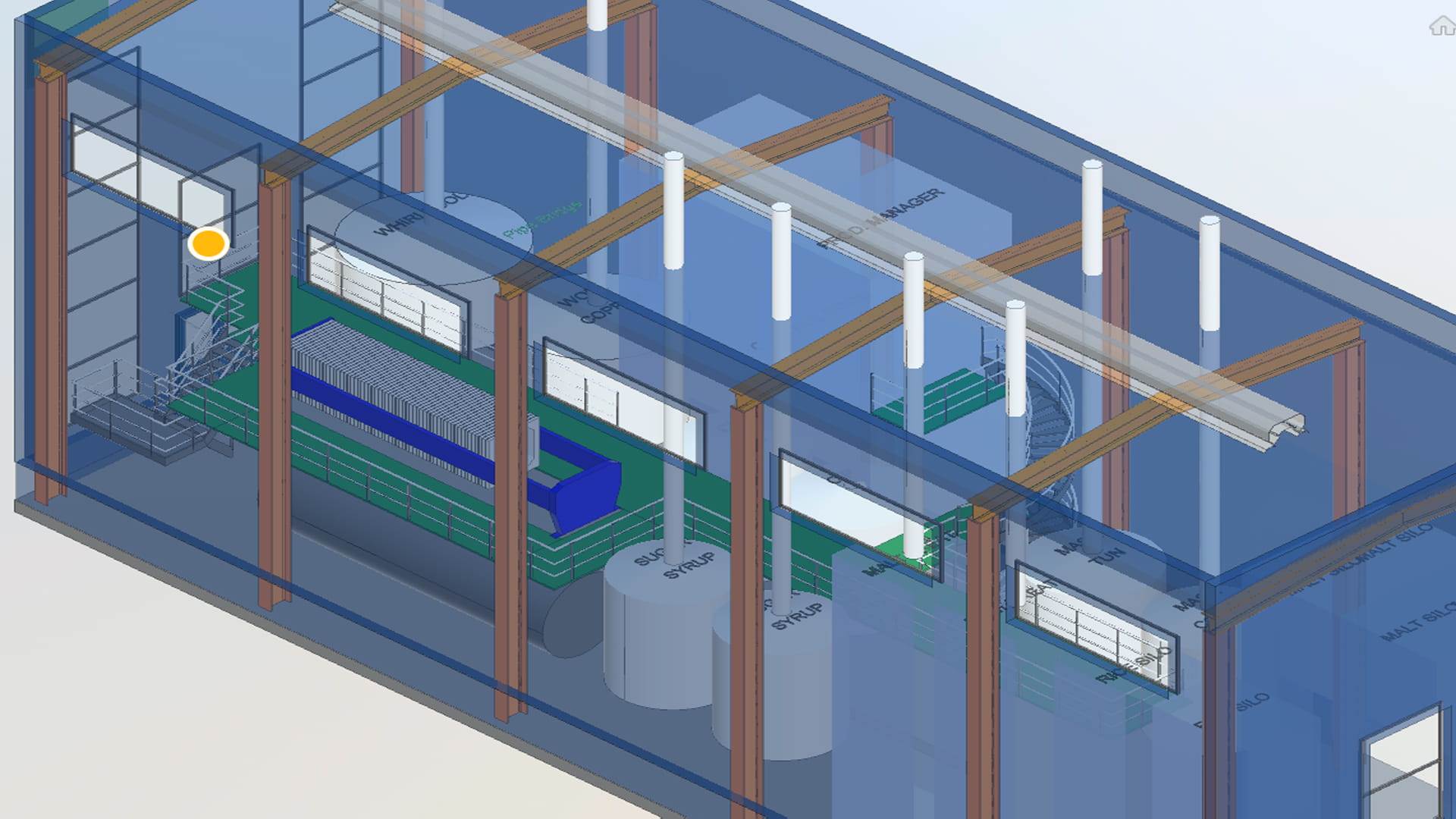

The solution - Smart 3D modelling

The solution lay in an economical approach facilitated by a comprehensive 3D model of the entire brewing process. During a site visit, it became evident that the existing brewhouse was no longer viable and required complete replacement. The plan involved demolishing the existing workshops to create room for a new brewhouse. This strategic move allowed production to continue seamlessly during the construction phase.

The result - Seamless transition

The limited available space made 3D modeling an invaluable tool. By meticulously modeling the brewery equipment, the team virtually constructed the entire facility. This approach ensured that every piece fit precisely within the confined area. Moreover, the 3D model allowed for layout optimisation, resulting in a cost-effective solution. The existing brewery could continue its operations until the transition to the new setup was complete.

In summary, the synergy of brewery operations, innovative planning, and 3D modeling enabled our client to overcome challenges and maintain their production flow.