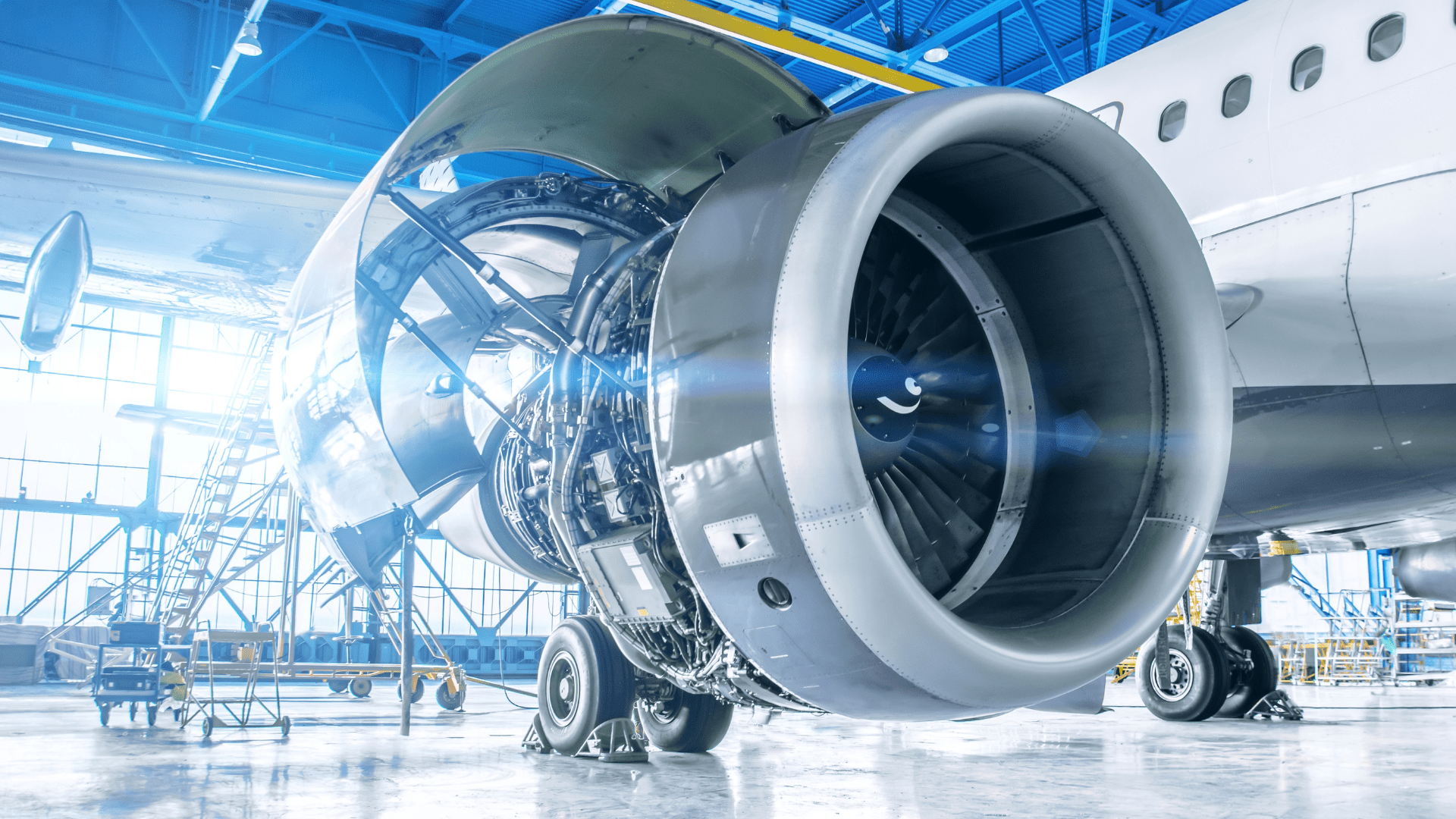

Aerospace

Complex and constantly shifting, the aerospace sector demands robust planning and agile reactions. Predictive simulation makes experimenting with multiple ‘what-if’ scenarios easy, so you unlock detailed insights and de-risk decision-making.

Discover moreDiscover more

Resource utilisation. Planning. Compliance. Delivery. How do you juggle the complexity while achieving commercial targets?

Predictive simulation simplifies these complexities. As a result, it’s become an integral decision-making tool for key industry players, many of whom use it in collaboration with Twinn Predictive Simulation Suite.With Twinn, you can easily create virtual models of real-life facilities and processes. You can test multiple ‘what-if’ scenarios and validate decisions relating to equipment, supply chains and operations in a risk-free environment – unlocking unparalleled business intelligence.

Boost through-life capabilities

Optimise customer value throughout the product lifecycle.

De-risk decision making

Unlock data-driven insights to power evidence-based decision-making

Improve operational performance

Reduce lead times and boost productivity to drive sustainable growth.

Optimise MRO programmes

Without impacting new manufacturing and supply chain lines.

What’s the best way to increase capacity and boost operational performance while driving down costs? How can you optimise MRO programmes without impacting new manufacturing and supply lines? Where can you make changes to increase your through-life capabilities?

User-friendly, flexible and powerful, Twinn WItness uses virtual models of your processes and operations to help you find the right solutions quickly.

User-friendly, flexible and powerful, Twinn WItness uses virtual models of your processes and operations to help you find the right solutions quickly.

Improve operational performance

Predictive simulation and digital twins deliver a comprehensive overview of your operations – encompassing everything from personnel to stock levels and fleets.Our Twinn Witness predictive simulation software enables your to test and validate your plans in a risk-free environment. This helps you optimise current resources to reduce lead times and supports the creation of realistic KPIs based on robust data. Twinn gives you the power to respond to challenges with agility, meet deadlines and boost productivity.

Boost through-life capabilities

With predictive simulation software, you have the power to plan and deliver MRO programmes – including scheduling – without impacting new manufacturing and supply chain lines.As a result, you gain confidence in your capability to optimise customer value throughout the product lifecycle.

Unlock our proven approach

From strategy and planning to training and consultancy, we’ve worked with the aerospace sector for decades and have a history of providing successful, scalable solutions.As a result, we’re best positioned to help you maximise value from predictive simulation – whether you’re developing your own internal capabilities or leveraging our expertise.

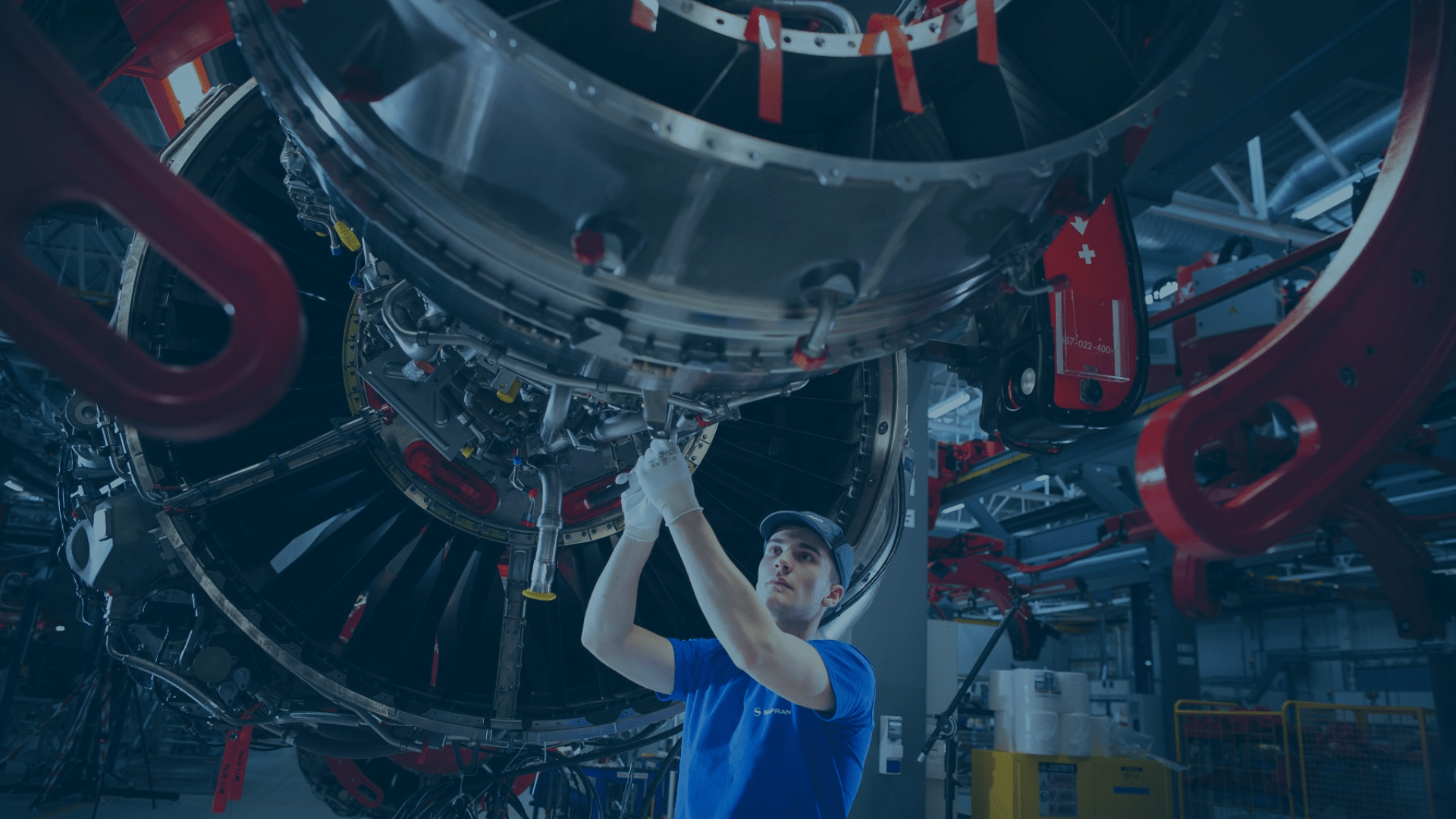

Impact Story: Safran Aircraft Engines

Safran used Twinn Witness simulation software to model their complex production lines, helping them to improve operational performance by optimising lead times and quality.

Twinn Witness Simulation Software

User-friendly, flexible and powerful, Witness gives you detailed insights into CapEx, continuous improvement and operational improvements before you invest.

Discover more