N2O emission reduction through smarter control at Apeldoorn WWTP

The application of Aquasuite Pure at Waterschap Vallei en Veluwe not only leads to improved effluent quality and energy savings, but also to a reduction in emissions of the greenhouse gas N2O. At WWTP Apeldoorn, it appears that a 90% reduction in N2O emissions is possible through smarter control.

Project facts

- Client

- Vallei & Veluwe

- Location

- Apeldoorn

- Date

- 2016 (commissioned)

- Challenge

- Stable operation of a WWTP with a high nitrogen load, with regards to nitrogen, N2O and energy.

- Solution

- Optimization with Aquasuite Pure for effluent improvement, energy savings and N2O emission reduction.

The challenge: stable operation of a heavily loaded WWTP

The Apeldoorn wastewater treatment plant (WWTP) was (and is) a plant that was (and is) heavily loaded in terms of nitrogen load, partly due to return flows from the sludge line. As a result, stable process management and achieving the effluent standard for total nitrogen was a challenge. In addition, a Quick Scan showed that situations with over-aeration regularly occurred with a negative impact on both total nitrogen and energy consumption of the aeration. Since aeration accounts for roughly half of the total energy consumption of a WWTP, over-aeration is an important factor. The emission of greenhouse gas N2O (265 times stronger than CO2) has also come under a magnifying glass by the water authorities. WWTP Apeldoorn has a high risk of significant N2O emissions due to the nitrogen load.The solution: reduce N2O emissions with Aquasuite Pure

In 2016, Aquasuite Pure was commissioned on both lanes of WWTP Apeldoorn, with various controllers including for aeration and internal recirculation (N&P). These controls use self-learning algorithms that can be used to make a good estimate of the required base setpoint. As a result, only subtle adjustments need to be made based on the fluctuating actual measured values to achieve the target values. The big advantage of this is that it anticipates what is to come instead of over-reacting to what is going on in the now. This results in a more optimal and stable operation of the waterline, which improves the functioning of the nitrogen removal process. This can reduce both the total nitrogen in the effluent and the N2O emissions and prevent over-aeration and save a lot of energy. Because the algorithms continue to learn and anticipate, this is a robust solution that also relieves the process operator.

Better effluent quality and N2O emission reduction go hand in hand

Aquasuite Pure is a reliable controller, which provides good and stable operations due to accurate DWA predictions. With very limited adjustments, good effluent quality is achieved and N2O emmisions are reduced. Even in unusual situations, such as when measuring equipment fails, Aquasuite Pure provides excellent results by using the learned predictions.

Process technologist at Waterschap Vallei & VeluweThe result: -90% N2O emissions, effluent improvement, and energy savings

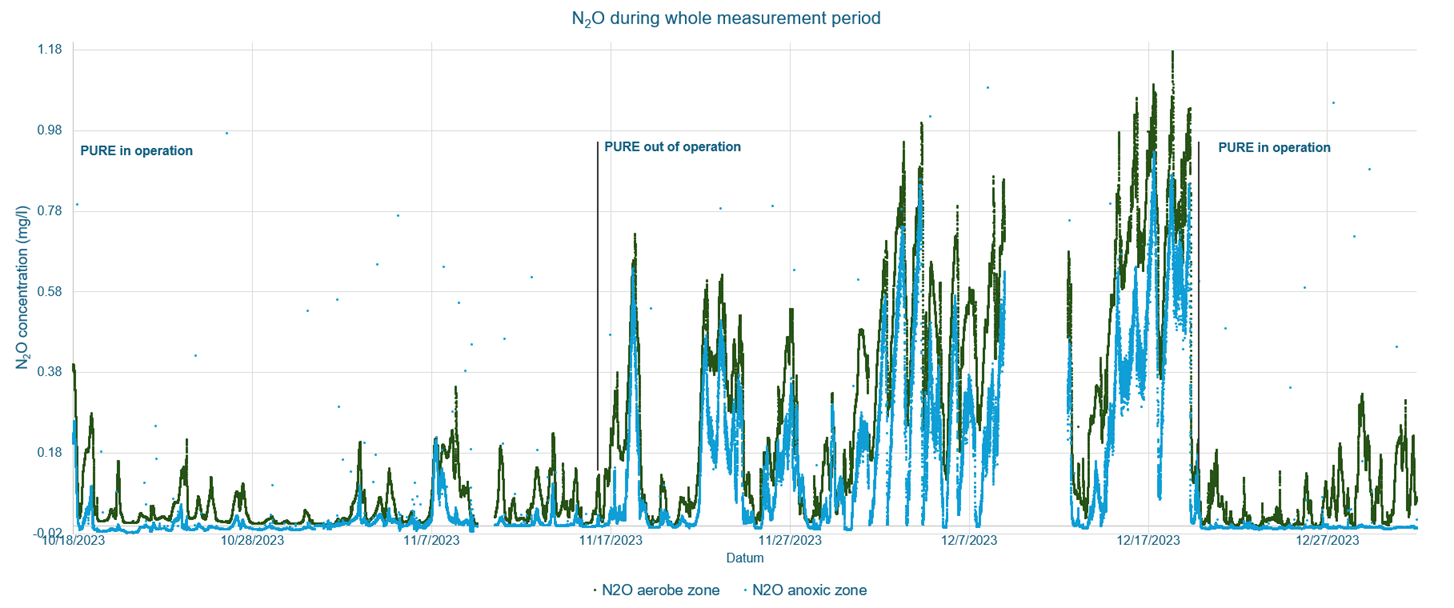

In mid-2016, Pure was commissioned at WWTP Apeldoorn and, apart from periods of major maintenance work, has been on almost continuously. However, in the fall of 2023, there was a period of communication failures and Pure was temporarily shut down. It was a blessing in disguise to be able to make a comparison between the Pure control and the local control. Especially because this fell in the middle of a measurement campaign in which the N2O emissions were mapped. The graph below shows the N2O concentrations.

Source: Waterschap Vallei en Veluwe

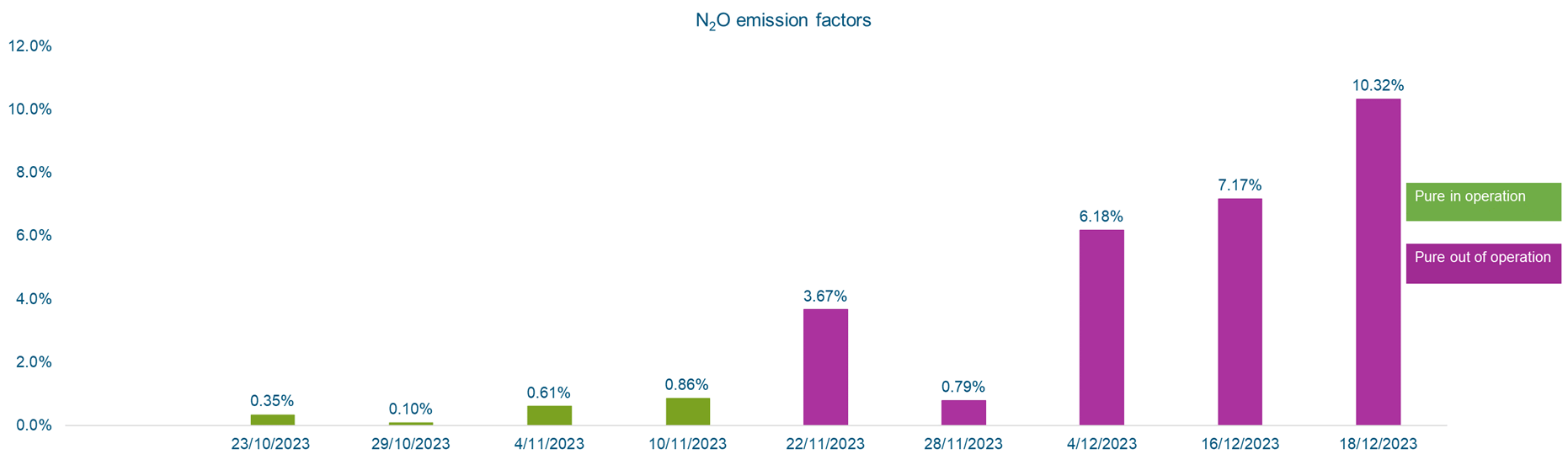

In a period of ~ 2½ months, Pure has been switched off for over a month. It is clearly visible that N2O concentrations are significantly lower with Pure in operation than with it not in operation. The graph below shows the N2O emission factors for the relevant period. Converted to emission factors, the average N2O emission with Pure in operation appears to be ~90% lower. In the same period with Pure in operation, the total dissolved nitrogen, orthophosphate, and energy consumption are respectively ~8%, ~22% and ~8% lower than with Pure out of operation.

Source: Waterschap Vallei en Veluwe

The result: a stable and reliable operation

In addition to the tangible results for the three "e's" (effluent quality, energy saving, and emission reduction), Pure also ensures stable and reliable operation 24/7. This allows the process operator to spend his/her scarce time more effectively. In addition, Pure, as a self-learning system, can counter the failure of measuring instruments by falling back on the prediction. As a result, the system is secured and controlled with the best alternative setpoint. This minimizes manual intervention.N2O mitigation by smart control is already possible

Really awesome to see that my very first Pure, which I configured in 2016, shows such good results. And not only in terms of nutrient removal and energy savings, but also in terms of N2O emission reduction. It shows that N2O mitigation by smart control is already possible and that this goes hand in hand with better and more stable effluent quality. Smarter control is a cost-effective way to get more out of existing assets in the foreseeable future.

Product Manager & Developer Twinn Wastewater

Want to learn more about digital solutions for the water sector?

Contact our Water Technology experts