Complete wastewater treatment with minimal equipment

Carrousel

Combining continuous biological aerobic degradation of organic and chemical pollutants (BOD/COD), nitrification, de-nitrification, and phosphorus removal in a single looped system, a Carrousel® WasteWater Treatment Plant (WWTP) offers a cost-effective treatment solution with an optimal compact footprint.

With a proven track record for reliable treatment of both domestic and industrial wastewater, Carrousel® WWTPs can serve populations ranging from one thousand to ten million people equivalent, adapting to all climate conditions.

A Carrousel® WWTP provides:

Highly efficient and cost-effective treatment

No maintenance required for underwater mechanical equipment

Fully automated operation and control

Continuous BOD/COD removal, along with simultaneous nitrification and de-nitrification processes in a single reactor

Optional phosphorus removal configurations (chemical or biological).

The process

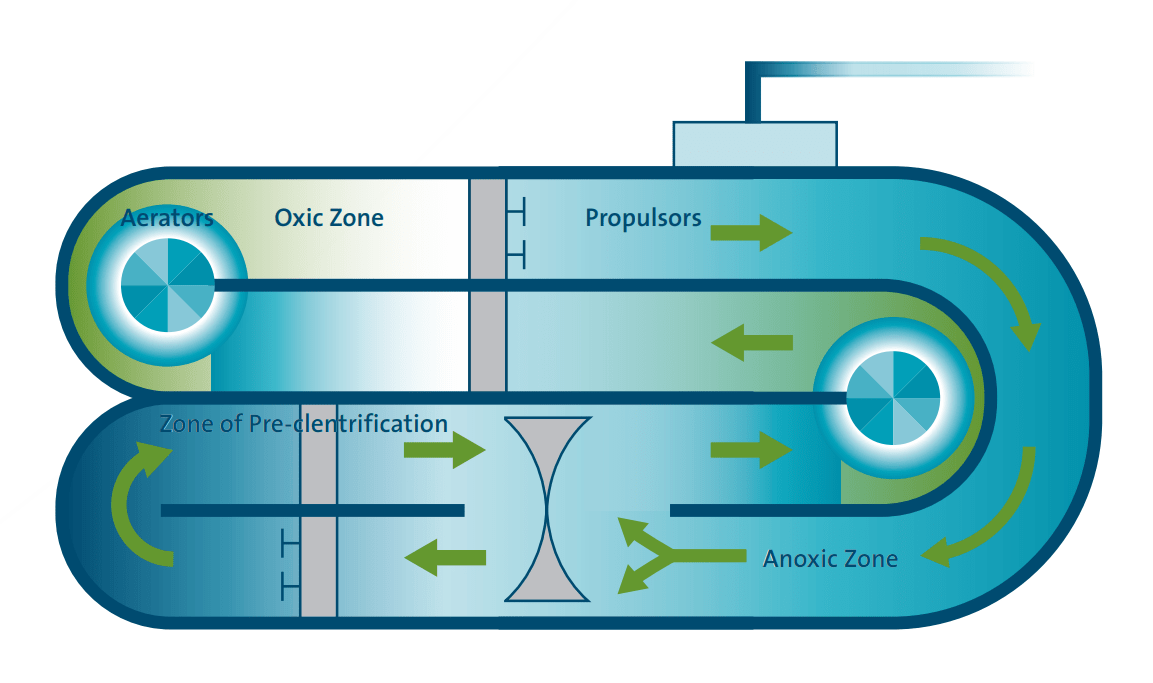

A Carrousel® system is an advanced oxidation ditch system that uses a looped channel system in a single reactor. It features a central dividing wall and low-speed surface aerators, at one or both ends of the dividing wall.

The surface aerator serves three main functions:

- Adding oxygen to the wastewater.

- Thoroughly mixing the wastewater and activated sludge.

- Boosting the flow circulating through the channels.

Initially, the aerator increases dissolved oxygen levels to optimize conditions for BOD/COD removal and ammonia oxidation to nitrate. As dissolved oxygen levels decrease, microorganisms use nitrate to oxidize any remaining organic pollutants.

Finally, treated effluent and activated sludge are separated (mostly) in a clarifier. Except for waste sludge, the sludge is returned to the Carrousel® system to maintain appropriate biomass concentration for continued wastewater treatment.

The benefits

Combining BOD/COD removal, phosphorus removal, nitrification, and de-nitrification processes in a single reactor, Carrousel® delivers complete wastewater treatment with minimal equipment, making it robust, efficient, and cost-effective.

Next to the standard system configuration Carrousel® offers three tiers in its configuration portfolio:

- Carrousel® 1000: Small capacity (standardized) system.

- Carrousel® 2000: Enhanced nutrient removal to meet stringent requirements.

- Carrousel® 3000: A deep Carrousel with a smaller footprint.

Operational benefits

- Simple civil structure for convenient installation and reliable operation, proven to last over 50 years

- Optimal footprint

- Robust and easy to operate

- Minimal equipment to maintain, no underwater equipment to maintain, maintenance that can be provided by own operational staff, resulting in low maintenance costs

- Optimal performance between the surface aerators and the Carrousel® system.

- Advanced control with Aquasuite PURE software, with or without remote operational support.

- Water depths of up to eight meters possible (Carrousel® 3000).

- Options for enhanced nitrogen and phosphorus removal (Carrousel® 2000).

- Options for covered systems with reduced odour and noise.