Welcome to Haskoning

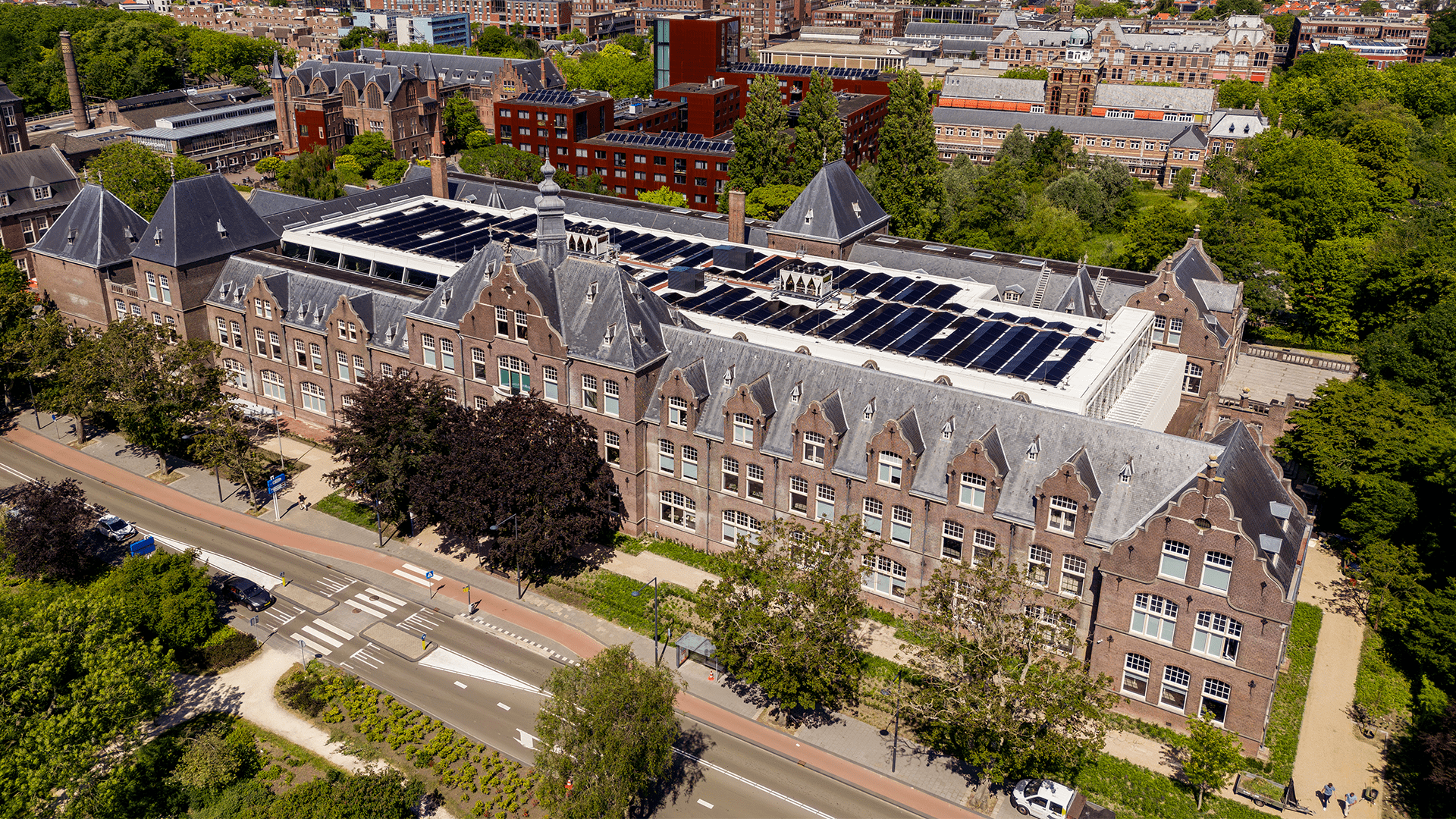

This iconic national monument from 1912 is the old Mining Faculty of Technical University (TU) of Delft. Since we purchased the building in 2021, a large-scale renovation has taken place until the official opening on 19 June 2025. The historical neo-renaissance character of the building has been combined with state-of-the-art technologies for 750 unique, modern workplaces. The result of this 'renovation with respect' is a beautiful sustainable office building near the Delft city center and the TU campus, and the second Paris Proof national monument in the Netherlands. The latter means, among other things, that we use 100% renewable energy and have achieved an 80% energy reduction, a leap from energy label G to A++++.

The choice to renovate, rather than building a new building, stems from our own expertise and sustainable values. Reuse saves on emissions from demolition and new construction (materials). That's a double win. And honestly, have you ever seen a new building with so much character? Moreover, the cultural-historical cityscape of Delft and the TU campus is preserved.

In the building's meeting rooms, you will find murals of projects that we have collaborated on. You can scan the QR code below the wall graphics with your phone's camera (app) for more information.

Below you will find more details on the sustainable components and technical highlights of the property's renovation.

Welcome to the Mijnbouwstraat 120!

Choice for Delft

The choice for a building on the edge of the city center and TU Delft campus is largely driven by the excellent connections via public transport and bicycle. In line with our sustainable values and goals, this reduces the need for individual car use. For those who do come by car, there are 30 charging stations behind the building. The electricity for these is partly generated by the 604 solar panels on the roofs of the atriums.

Way to go!

Window frames

Floating tube structure

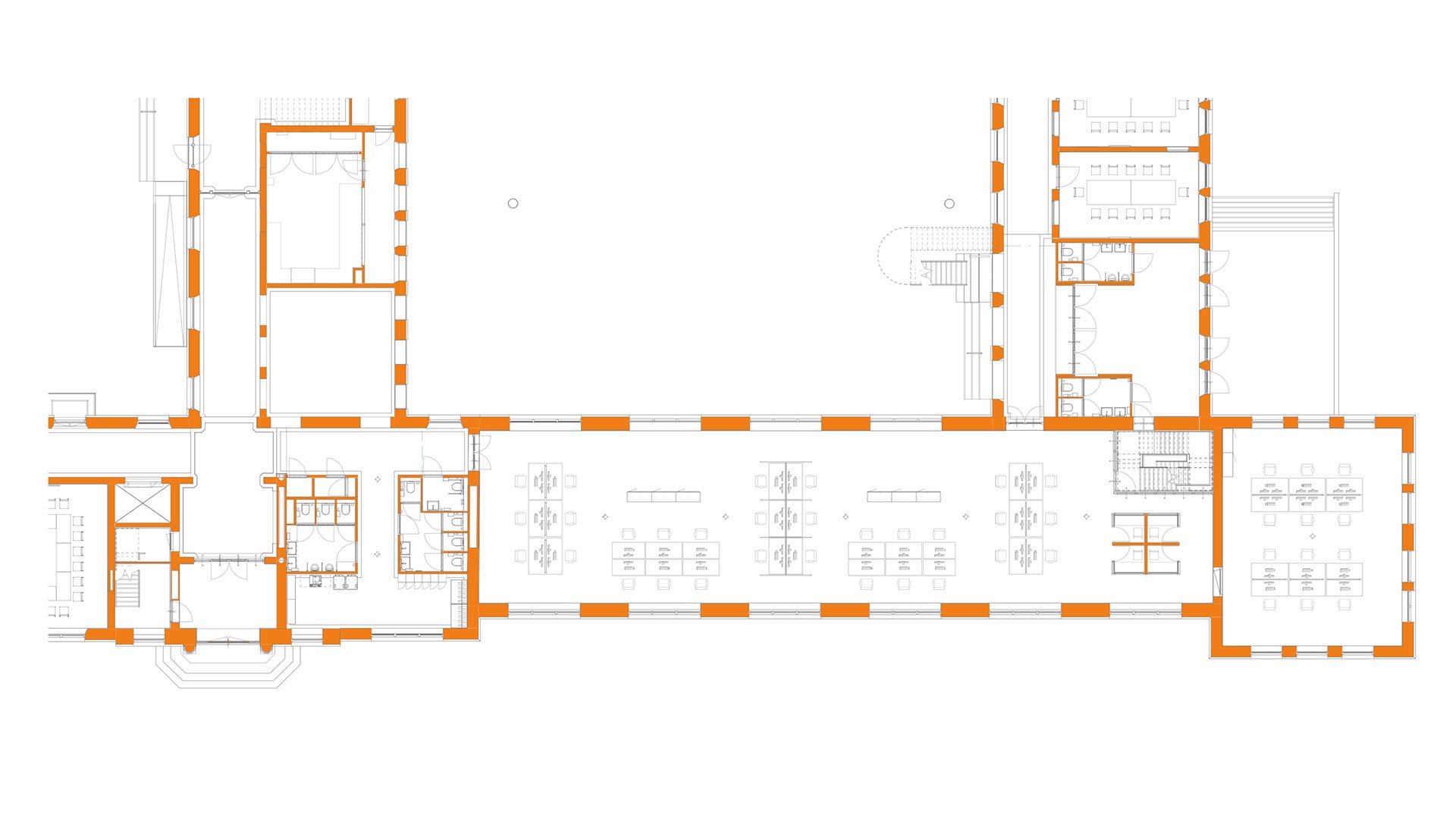

To make this historic building Paris Proof, so in line with the property energy consumption requirements for 2050 as outlined in the climate agreement, out-of-the-box insulation solutions had to be devised. One of those solutions is reducing the surface area of exterior walls, as most heat loss occurs there. By covering the two courtyards, the surrounding exterior walls became interior walls. However, since the this is a national heritage site, it had to be done in a way that did not affect the building. To achieve this, our engineers designed a floating metal tube and glass structure with enough load-bearing capacity for the 604 solar panels on top -in harmony with the building's historic character. No less than six night-time road transports were needed to transfer the enormous structure. Covering the courtyards also added meeting and working space to increase the building's capacity.

Follies & fossils

These follies are reused floor gratings from an old coal factory. With us, the grates function as screens to divide the atria into smaller corners where you can work and meet quietly. The contrast between the polluting fossil industry they come from, and this fossil-free, Paris Proof building could hardly be greater.

Nice to see the life of these materials come full circle.

Self-generated sustainable electricity

Right on time

This is the second Paris Proof national monument in the Netherlands. Paris Proof refers to the Paris climate agreement and practically means that energy consumption of a building is reduced by two-thirds and renovation is done within a CO2 budget. Quite a challenge for a national monument. In the case of this building, it meant a journey from energy label G to A++++, with a consumption of less than 70kWh/m2/year. This was achieved by exchanging fossil energy sources for heat pumps and geothermal energy, constructing atria for insulation, installing solar panels and user-driven climate control. The calculation of emissions from energy use is done using the Actual Energy Intensity Indicator (WEii), and material-related emissions are determined using the Paris Proof material-related indicator (PPm-indicator).

Ready for 2050

Built with less material

This counter is 3D printed. The technology allows users to create automated shapes and constructions that are not possible with traditional manufacturing methods. Not only does it look interesting, but it also offers advantages in terms of material usage and function. For example, we also apply this technique in infrastructure such as pedestrian bridges. This way, a lighter yet stronger construction can be built with less material. This counter was manufactured by our partner Netcam, in collaboration with our own civil experts.

Roof trusses second floor

The roof trusses in the attic are partly made of metal (in the old museum wing) and of wood. A significant portion of the wooden trusses (and other wooden roof parts) was in a deplorable state due to moisture when we purchased the building. All rotten parts have been restored to their original state, and the trusses have been thickened and reinforced with a steel pull rod in order to be able to bear the new sprinkler/climate installations and pv-pannels on the roof.

New bat boxes

An ecological study we commissioned revealed that dwarf bats are present on the exterior of the building. Therefore, during the renovation, we installed replacement bat boxes in the vicinity and embedded new bat roost boxes into the facade.

The guiding principle

Sustainability in this building is not a layer of 'corporate varnish' added afterwards; it has been the foundation of the idea to establish our office at this location in this way. This is evident in the visual overview, where our experts in circularity and emissions have meticulously outlined where our footprint around this building lies. It has been the guiding principle of how we approached the renovation, what we have reused, and what we have done with new materials. In the image you can see how we spent our 'CO2 budget': the distribution of emissions over the components used.